We conduct underwater inspections worldwide

Founded to change the industry

Over 30 years of experience in the field

With decades of combined experience within the subsea inspections and ROV industry, a couple of friends started looking beyond the traditional ways of conducting subsea inspections.

Setting the global standard for sustainable subsea inspections

Our vision is to deliver a greener, more sustainable, and affordable subsea inspection solution. With our superior and revolutionary mini-ROV system, we want to set the new standard across the globe for small- and large-scale subsea inspection operations.

Revolutionizing subsea inspections: a greener, safer future with BeyonC AS

Traditional subsea inspections methods are reliant on shifting vessel schedules and complex mobilizations, often requiring the hazardous operation entering the Assets Safe Zone.

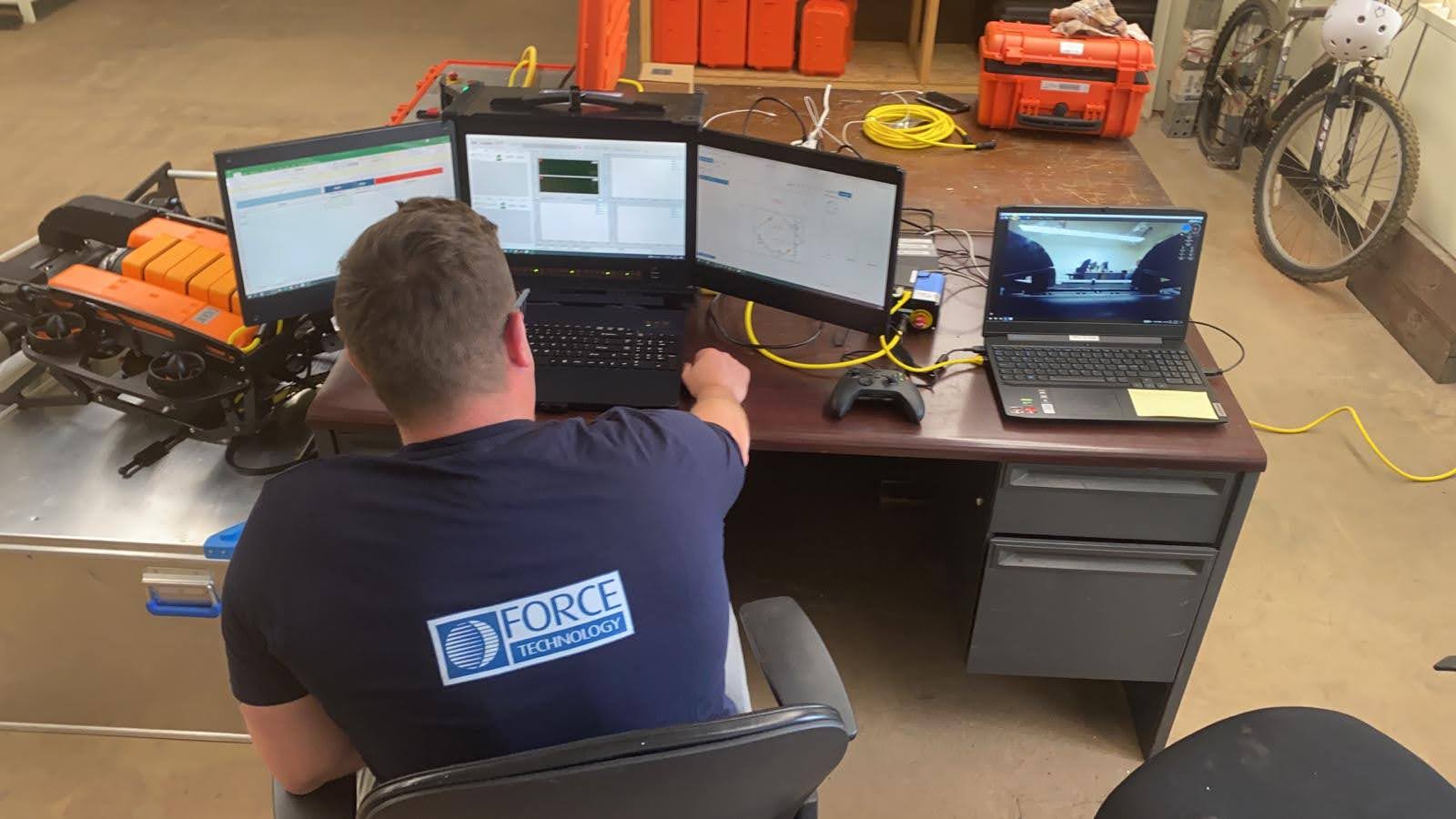

Our focus turned towards a greener, leaner future, and so BeyonC AS was founded to change the industry. Together with important partners like JM Robotics® AS, FORCE Technology Norway AS and EEST Energy Services we are streamlining the subsea inspection industry worldwide.

How it all started

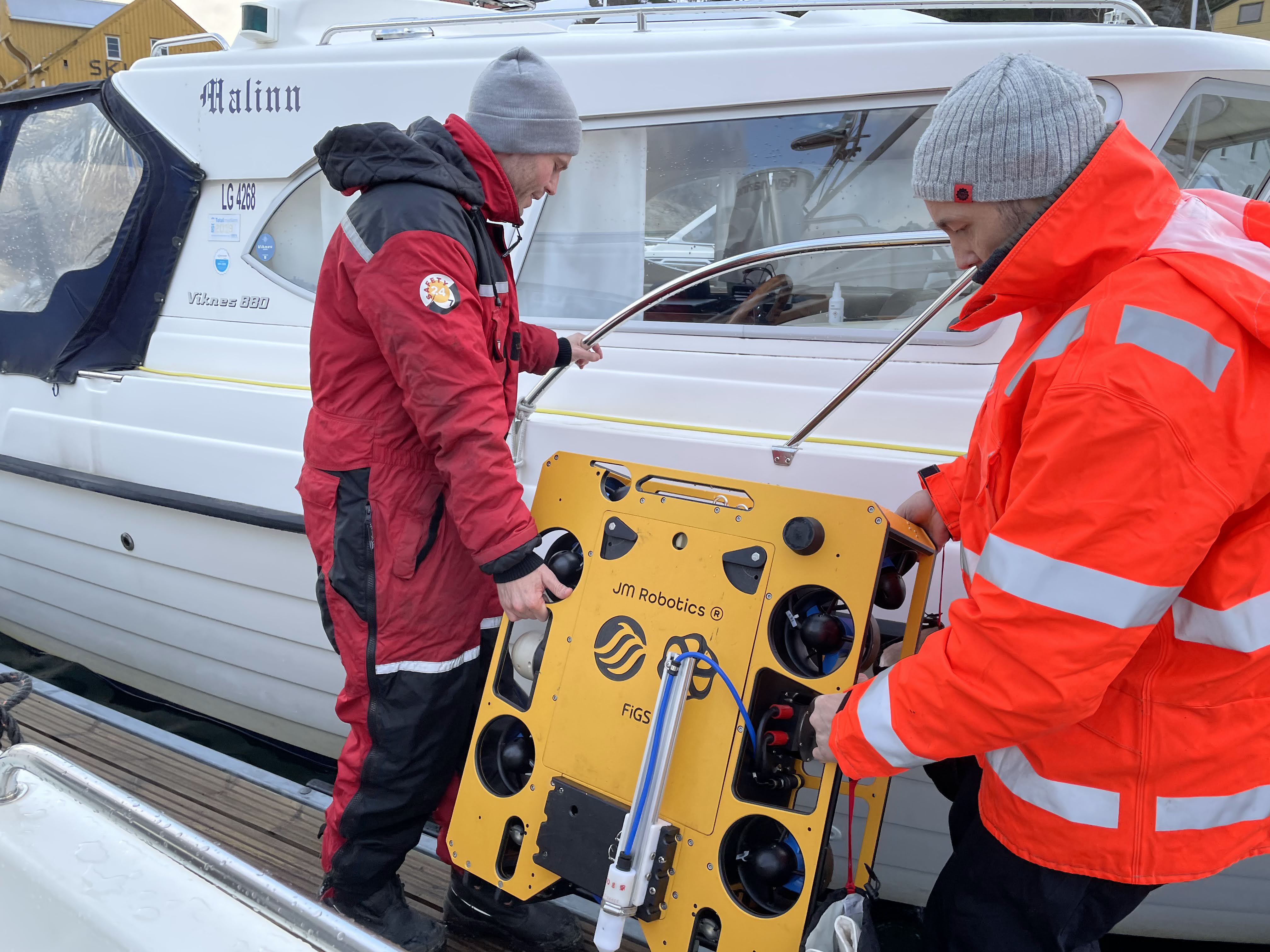

Tailored ROV for FiGS-inspection

Inspection was done in 1 shift (12H).

Opportunity:

Reducing cost if CP data collection

Improve quality of CP survey data, reduce cost of CP data collection by add-on to Mini-ROV (instead of work-class ROV) UWS inspection initiative, ability to determine accurate remaining life of UWS and CP modelling:

- Reduced offshore vessel time and eliminate diving

- Efficient & accurate CP System inspection/testing

- Optimize retrofit design and costs

- Predicted time to next inspection

- Comprehensive CP Systems integrity assessment part of routine Subsea Survey

Solution:

Deploy FiGS® with mini-ROV

Result:

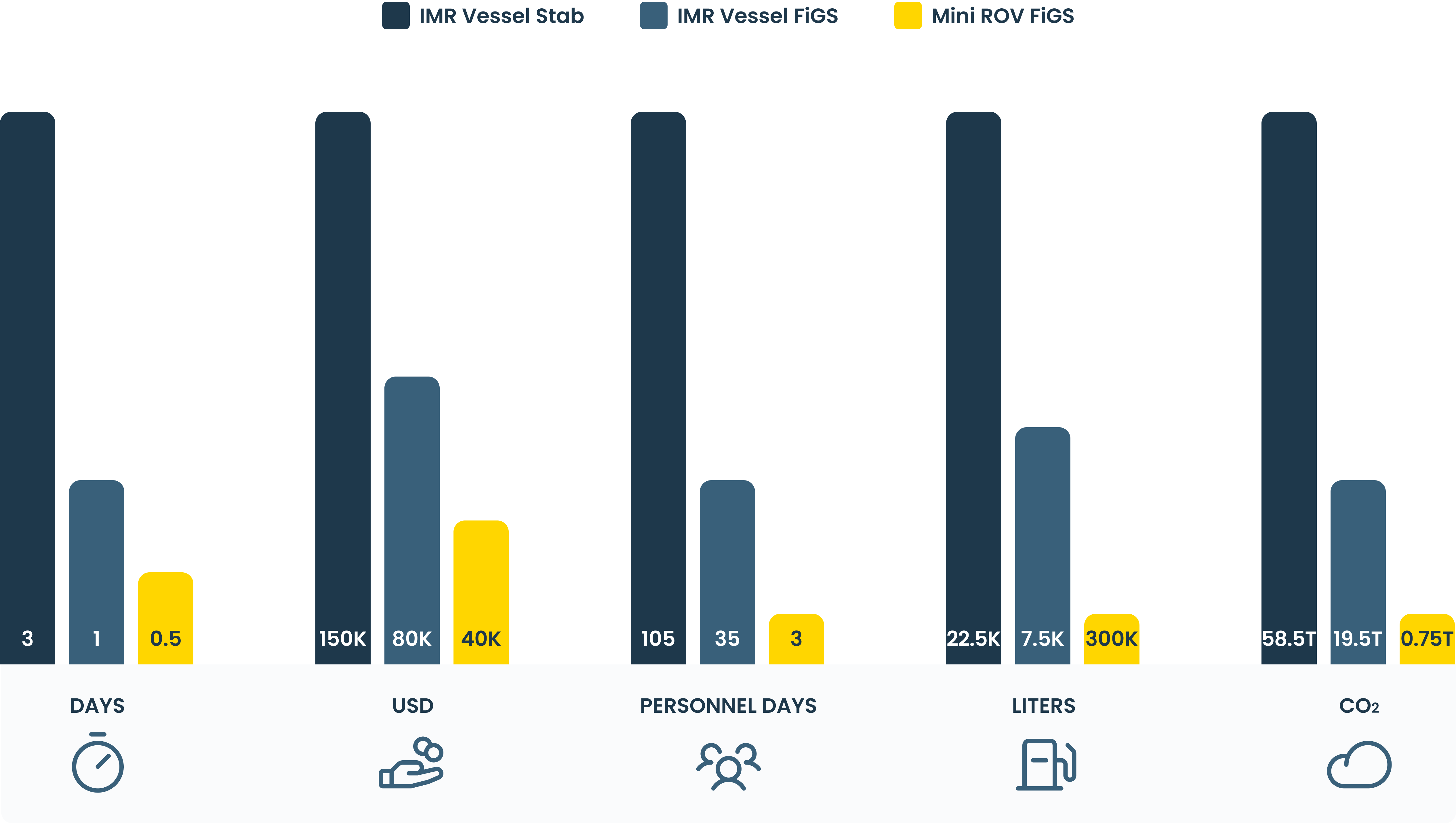

Productivity can increase by about x5

Business Impact:

Improved productivity ~500%

Savings $300K

FiGS survey $25K/jacket vs. Conventional CP survey ~$300K.

Jacket inspection:

IMR Vessel V.S mini-ROV (CP stab and FiGS®)

Finding solutions to reduce the cost of underwater inspections

Timeline

10 of June 2021

First meeting in Kristiansund. Initial flying test.

11-29 of June 2021

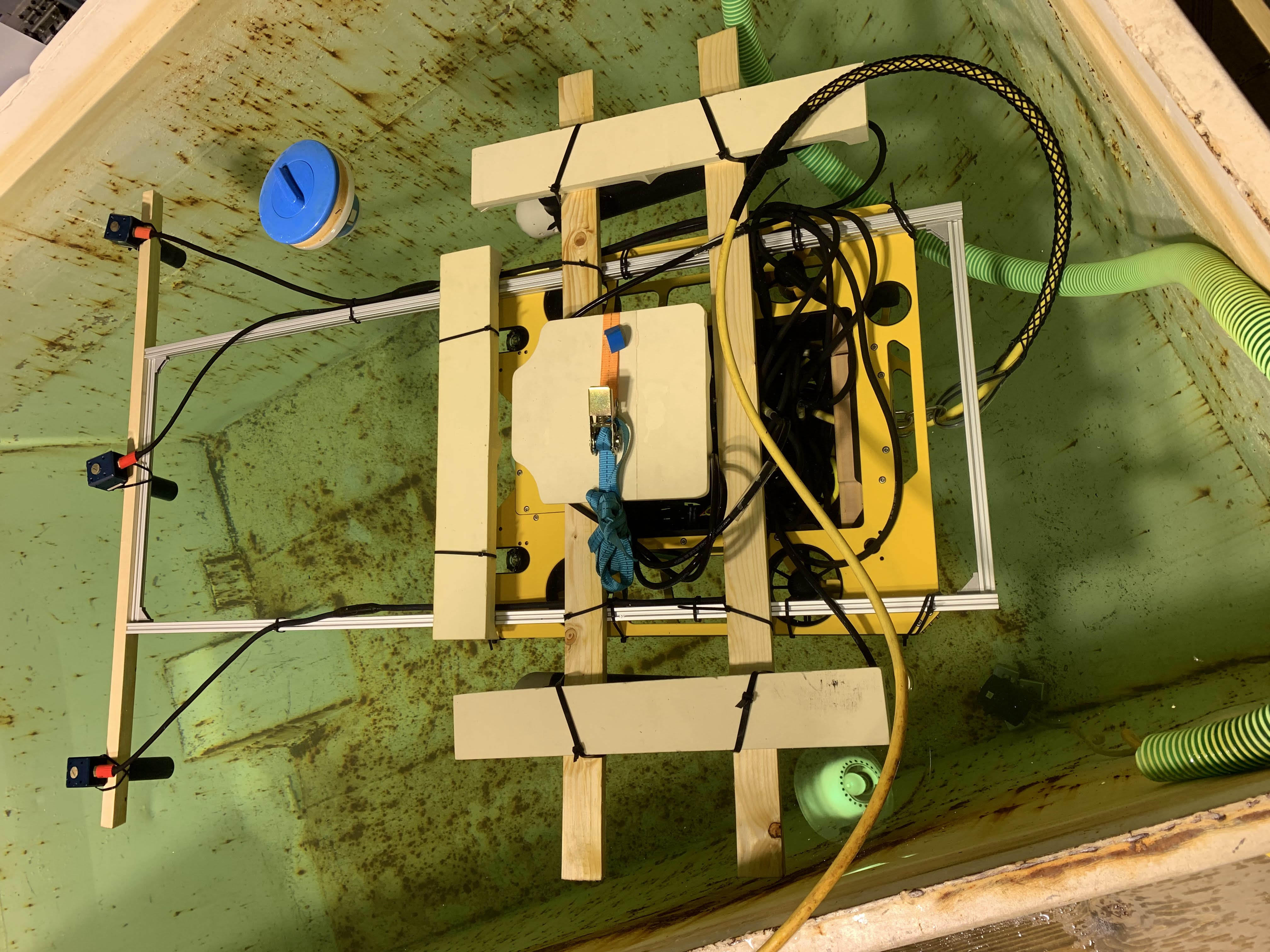

Phase 1: Build proof of concept solution.

29 of June 2021

Testing of prototype.

23 of August 2021

Equipment arrived in Angola for first deployment.

07 of September 2021

Proof of concept achieved after 2 weeks off successful deployment.

November 2021 - February 2022

Phase 2: Development of tailor ROVs.

2 concepts to be developed:

- Tailor made ROV for Jacket inspection.

- Additional skid to add on a Jacket ROV for pipline inspection.

14 of Deceember 2021

Status: Tailor made ROV for Jacket inspection and first testing of pipeline inspection setup for Jacket inspection.

8 of February 2022

Status: Tailor made ROV for Jacket inspection.

19 of February 2022

Status: Second testing of pipeline inspection setup for Jacket inspection ROV.

25 of February 2022

Sea trials.

15-17 of March 2022

Product lounch in Oceanology.

September - December 2022

Phase 3: Improve pipline inspection ROV:

Update USBL/DVL to survey grade positioning accuracy:

- Build new skid for ROV.

- Integrate survey positioning wquipment.

- Upgrade sonar

02 of December 2022

Testing installed equipment under the water.

15 of December 2022

Field test with the client.

28 of March 2023

FAT-test ready to be shipped to Angola.

Get in touch to cut costs and boost the efficiency of your inspections

BeyonC AS: worldwide subsea surveys